Wrought iron metal working has been around for centuries. What was once the mark of experienced craftsman and blacksmiths, has since been replaced by machinery and automation.

Mass production has replaced what were once one of a kind works of art with cheaply made replicas. Often times using sub-par materials like cast iron or iron alloys. Built simply to last “long enough” and no longer forever.

However, custom wrought iron work is still in demand today. Unfortunately, there are very few master craftsmen today producing products from wrought itron. For those left with the knowledge, patience and drive to forge forward with their unique skillset, it can be very lucrative.

A technique once used for producing spikes, nails, horse shoes and wagon wheels has now crossed over to high end living and custom architecture. Wrought Iron fencing, railings, doors and furniture are all in high demand.

Having custom, one of a kind items, not available for purchase from a store, is something homeowners and businesses are willing spend big money for.

Mistaken Identity???

Before getting too far, I’d like to take a second to address the name “wrought” iron. Wrought is a past participle of work. Simply put, it means iron that’s been worked.

Such as by a blacksmith shaping iron ore into something. However, there are many mispronunciations and spellings commonly used by mistake.

Rod iron, Roth iron, Wrought iron, Wrot iron and Rawd iron are all used mistakingly. So from this point forward, we will call it by its correct name. Wrought Iron

What is Wrought Iron?

True wrought iron comes from iron ore. Iron is one of the most abundant elements on earth. To produce it, a refining process of smelting iron ore to remove impurities is needed.

Extreme heat reduces the ore to its purest state, known as pig iron. Another refining process is used, melting pig iron to a molten state. Stirring it with a stirring rod in the molten state eposes the iron to oxygen.

As result, decarbonizing it. Little balls of molten pure iron are collected using the stirring rod. Also referred to as blooms. Blooms are then worked or hammered into lengths of bars, sheets, or rods.

Once produced, it can be reheated, allowing it to be worked iron, shaped and formed into its intended use.

How is Iron Different from Steel?

The main difference between wrought iron and steel is the amount of carbon each one contains. Wrought iron contains a very small percentage. Less than .01%.

Steel has carbon added to it in order to give it strength. However, carbon makes the steel brittle. As result, steel goes through a hardening process known as heat treating.

Heat treating is a process of heating steel and then quenching it. As. result, changing its makeup. This process hardness the steel.

Wrought iron is a true metal, softer and more malleable than steel. As result, shaping and bending it is easier than steel.

It also contains fibrous slag inclusions. This slag gives it a grainy look. Similar to that of wood grain. It is strong yet easier to work by hand. Furthermore, the low amounts of carbon make it more corrosion resistant than steel.

Steel is not a true metal. It is actually an alloy, not natively found on earth. It it much easier to produce. A large percentage of steel produced today comes from recycling old steel.

As a result, making it more affordable. Steel is also harder and stronger. Better for construction and building. Because it is harder, it is also better for cutting tools and intensional. Hardened steel holds and maintains sharp edges without cracking or breaking.

Uses for Wrought Iron

For centuries people have made things from wrought iron. Many of the items produced hundreds of years ago are still around today.

Tools and necessities like nails, spikes, horseshoes, and weapons made from it aren’t as popular today. However, wrought iron items like custom doors, furniture, railings and fencing are in demand.

The price of these items are not cheap. If a one of a kind work of art that nobody else will ever have is what you’re looking for, it is going to cost you!

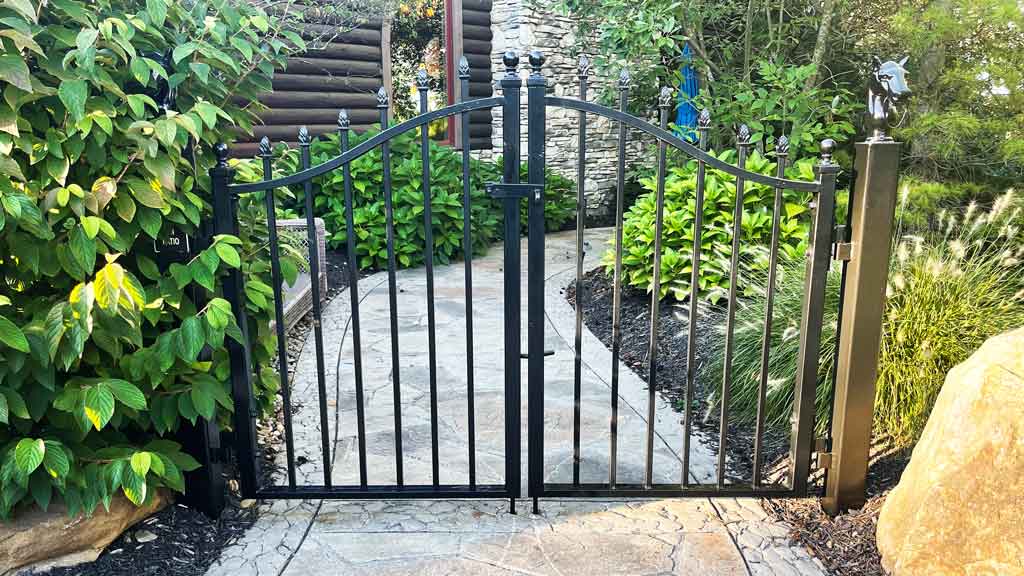

Wrought Iron Fencing

Wrought iron fencing has been around for hundreds of years. It is strong and durable. Requiring very little maintenance. Made to last a lifetime or even longer.

In Westminster Abbey in London, there are gates dating back to the 13th century made from it. It is elegant and classy. At the same, it gives the impression of ultimate strength and security.

Fencing styles range from very simple to very ornate. The addition of scrolls, finials, and rings adds to the character. Any height and style configuration is possible because they are custom.

The total footage of fence, combined with the complexity of the design will determine the price. Having one Installed adds value to the property.

Wrought Iron Railings

Wrought iron is a very popular material for constructing railings from. The malleability allows for it to bend and twist to any design.

Custom railings accent entryways of commercial buildings and churches. However, they are also found used for indoor railings for homes.

Two common uses for indoor railings are staircases and balconies. They are sturdy and secure, a must for protection. Just like the fencing, they are extremely customizable.

Wrought Iron Furniture

Throughout time wrought iron has been used to create furniture. Or at least parts of furniture. Tables and chairs are common items. The strength it offers provides solid platforms for tables and chairs.

Park benches made from it last decades or longer. Cheap metal furniture found today doesn’t compare in strength or durability. Elegance is another feature not found in furniture today.

Classic craftsmanship of one of a kind pieces of furniture make elegant statement pieces. Although costs associated with this type of furniture are higher, their durability and longevity pay for themselves throughout the years.

Wrought Iron Doors

A beautiful, hand crafted wrought iron door will give any house a wow factor. The custom styling adds to the curb appeal of a home. The strength makes it better than doors constructed from other materials.

They are stronger and more secure than any other type of door. As a result, they are almost impossible to damage. A true deterrent to potential burglars.

Unlike wood doors, they won’t warp or rot. They are also resistant to moisture, fires and insects. Investing in one provides a lifetime of safety and security.

Other Iron Items

Just take a look around the house and you’re sure to find something made from wrought iron. Common items include wine racks and pot racks. Anything that requires durability or longevity uses it.

Curtain rods, candelabras, book ends, and fireplace utensils are just a few examples. Anything from hinges to plant stands. If it was intended to be purchased once, and built to last, there is a good chance it was made from wrought iron.

Conclusion

Finding a true craftsman to produce these one of a kind treasures is the challenge. Wrought iron is no longer commercially produced. The tradesmen who work with it are also a dying breed.

As a result, the costs will be high. However, being the owner of a one of a kind work of art is worth paying to some. When a source cannot be found to produce the piece you are looking for, try a repurposed piece.

Old wrought iron items that are repurposed is the latest in trends. A story to go with a repurposed piece adds to the elegance. Just be aware of fakes and reproductions. Even repurposed pieces are pricey.

By now you’re seeing a common theme in regards to wrought iron. It’s customizable. Any design, pattern or look you want you can have.

It is durable. Lasting for decades if not centuries. It has little to no maintenance. While it may occasionally rust, it doesn’t rust as fast as steel.

It is strong! Great for doors, railings, fences and furniture. It’s elegant. Hand crafted works of art. Nobody else can duplicate. It adds value. All of these are advantages wrought iron has over other types of metals.