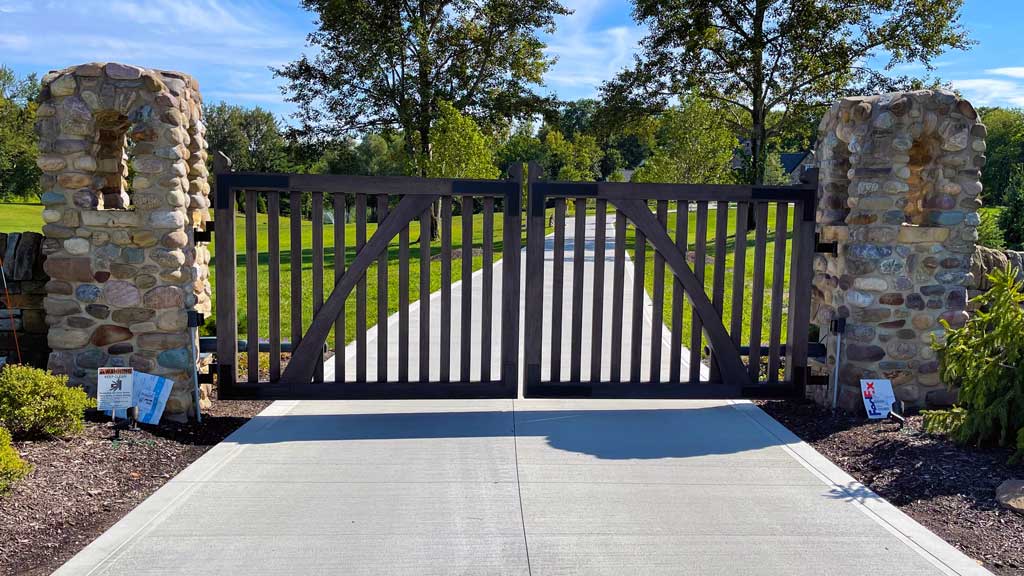

Driveway gates provide security keeping unwelcome guests out. Installing a gate across your driveway or to the entrance way of a business not only adds a statement piece to the property, it also adds functionality.

Furthermore, they keep children and pets safe and secure. Built from many different types of materials, driveway gates range from very simple single panels composed of welded pipes, to ornate works of art constructed from aluminum and wrought iron.

Manufactured in endless variety of styles and configurations. As a result, choosing the best one for your needs can seem like a daunting task. However, we’re here to help.

In this article you’ll learn about materials used to build gates, the different types of driveway gates, and we’ll also touch on automatic gate operators and access controls.

Types of Materials Used to Build Driveway Gates

Wrought iron, steel, aluminum and wood are materials manufactures use to build and construct gates. Certain materials have advantages over others.

The style and look you are trying to achieve will determine what materials your gate should be. Other factors will be how wide, tall, and how often you will use the gate.

Wrought Iron Driveway Gates

The longest lasting, most ornate gates you’ll find are wrought iron. The strength and durability of iron used to construct these gates mean they’ll last a lifetime.

Custom designs are achieved by welding wrought iron together. From very simple to very ornate designs, if you are are looking for a truly custom look, then wrought iron is the way to go.

However, there are two concerns you should consider before choosing a wrought iron gate

Wrought iron gates can be expensive. Very expensive! There aren’t many companies that build true wrought iron gates and fence. Working with wrought iron is an exceptional craft that takes years of experience to master.

These craftsman are few and far between. As a result, they charge a premium for their services. However, if a one of a kind gate that will last a lifetime is your goal, and your budget allows it, then a wrought iron driveway gate is for you.

Rust is the second concern. An iron gate with even the best of finishes is going to need painted at some point in its life.

Under normal circumstances, there may be decades between paint jobs. However, if you live in a northern climate where snow is abundant, then rust and corrosion can increase the frequency between paint jobs and or maintenance on your wrought iron driveway gate. Here’s why.

Driveway gates are normally located near the road. When winter comes, so do the salt trucks. The salt spray caused from wet roads and car tires lifts salt into the air.

In many cases, salt spray lands on the gate. Overtime, this can cause rust or corrosion to your gate.

Steel Driveway Gates

Steel driveway gates are similar to wrought iron gates except that most use steel tubing instead of solid steel. This means that the square or round pieces of metal used to fabricate these gates are hollow. This results in a lighter weight gate, that is also less expensive to build.

Fence manufacturers offer steel driveway gates in a variety of standard styles. Height, width, and color are available options. Exposed points with pressed spears or finials and flat top styles are standard. Along with straight across the top or arched versions.

Not as strong as wrought iron, steel gates are strong enough to provide adequate security while at the same time saving some money. However, just like wrought iron gates, the rust and corrosion factor comes into play when located next to roadways with high amounts of salt spray in the winter.

Aluminum Driveway Gates

Aluminum driveway gates have a couple advantages over other materials. They don’t rust like iron or steel gates can. In areas where road salt spray is a concern, they can last longer without the maintenance.

They are lighter in weight which allows them to hang from smaller posts or brick piers. The lighter weight also comes into play when automating a ornamental aluminum driveway gate.

The lighter weight puts less of a load on gate operators. Many times allowing for a smaller lighter duty unit. As a result, saving you money!

Much like steel gates, there are many standard styles of aluminum driveway gates. Making them more affordable than custom gates constructed from more expensive materials. Straight across and arched models are standard.

Most aluminum driveway gate manufactures offer powder coated finishes in a variety of colors. Finials, rings and scrolls are all standard accessories.

One thing to consider when choosing an aluminum driveway gate is security. While most people would not be able to tell the difference from the road, aluminum gates are not as secure as steel or wrought iron.

Aluminum is lighter in weight and strength. The pickets or spindles can bend or cut more easily than steel or iron. If maximum security is the priority choose a wrought iron or steel driveway gate.

Wood Driveway Gates

Wood driveway gates are perfect for projects when ornamental gates just don’t fit the look. However, wood gates have challenges that metal gates don’t.

Wood gates are heavy. And because you cannot weld wood together like metal gates, problems with staying square and or sagging can arise. Large steel reinforcement brackets help support the junctions of wood driveway gates. Sometimes, an entire steel frame supports the gate with the lumber fastened to it.

The type of wood used for the gate is also important. Most wood has a tendency to warp or twist throughout the drying process. As a result, wood gate manufacturers choose lumber types that stay true once cut.

Cedar and Redwood are popular lumber choices for wood driveway gates. Once cut, they stay straighter than pressure treated lumber does. At the same time, they are also more affordable and readily available then exotic lumber types.

Driveway Gate Designs

Driveway gates come in a variety of designs or configurations. Single leaf, double leaf, cantilever or sliding and vertical lift gates are all used for driveway gates.

How wide of an area you are trying to cover and the amount of daily traffic can influence the design of your gate. A narrow entrance might only require one gate. A wider entrance or driveway may require two gates that meet in the middle.

Choosing the correct type of driveway gate is crucial. In order to make the right choice you must first have knowledge of how each gate design functions. Next, learning the advantages and disadvantages to each style will help you to narrow down your choices.

Let’s take a closer look at each design!

Swing Gates

Swing gates are the most popular design for driveway gates. A swing gate panel is called a “leaf”. Single leaf and double leaf swing gates are standard. Single leaf gates cover shorter distances. Double leaf gates cover up to twice the span of single leaf gates.

Swing gates operate easily, hanging across driveways, while swinging to allow access. Most swing only one direction. Room is needed to open at least 90 degrees from the closed position. Gates opening towards streets must be recessed to allow entry to the driveway with room to open without striking a vehicle.

Gate location should be level or sloping away from opening direction. Upward slopes in the direction gates open prevent them from opening completely, unless installed at a higher level.

Snow is the biggest disadvantage to swing gates. Deep snow in front of gates must shoveled before opening to prevent stress to hinges and posts.

Cantilever and Sliding Gates

Cantilever and Sliding gates roll perpendicular to gate openings. As a result, they require extra room to the side of the gate opening.

Unlike swing gates, cantilever and sliding gates roll parallel to the fence line or wall. Therefore, they require little room in front or behind, working well when recessing the gate away from the road isn’t an option.

Unlike swing gates, only room enough for a vehicle pull off the road is required for gate operation. Compared to other gates, sliding and cantilever gates open faster when controlled by an electric operator. In situations with high amounts of traffic, this can be a huge time saver.

Another advantage is in Northern climates where snow is heavy. Only the width of the gate (usually 4″ or less) needs to pass through the snow. Far less than swing gates require. Making these gate designs popular where snow is prevalent.

What’s the Difference Between a Cantilever Gate and a Sliding Gate?

Cantilever Gates

Cantilever gates cover the opening without any part of the gate touching the ground. To achieve this, cantilever gates have an extended tail called a counter balance. The counter balance holds the gate off of the ground when closed.

There is no need for a roller or wheel at the leading edge of the gate. Helpful when the grade is uneven, the driveway is stone or gravel, or in areas with lots of snowfall.

A downside to cantilever driveway gates is the counter balance adds 50% to the length of the gate. For example: A cantilever gate covering a 20′ wide opening has a 10′ wide counter balance. Therefore, the total length of the gate will be 30′ long. 30′ of space is required in the direction the gate will open. Figure 1-1/2 times the gate opening when planning for the space needed to fit a cantilever driveway gate.

Sliding Gates

Sliding gates function just like cantilever gates do, rolling parallel to the fence line or wall. However, there is one major difference.

Sliding gates do not have counter balances. As a result, they don’t require the room a cantilever gate does to open. In order to stay supported a sliding gate will have a wheel on the leading edge of the gate.

Many times this wheel will roll in or on a metal track that is installed across the driveway. A level surface is required for sliding gates to operate correctly.

However, because a track is required on the ground level, sliding gates do not work well in areas with snow. Especially where a snow plow will be requires for snow removal. Gravel or stone driveways should also be avoided when considering a sliding gate.

Vertical Lift Gates

Vertical lift gates are gates that lift into the air. Like the arms in a parking garage. Vertical lift gates are faster operating than other gates designs. However, they require an electric operator. The gate and operator are fabricated as one unit.

All other designs discussed above can be operated manually. They don’t require power or the extra cost of an operator.

Because vertical lift gates are designed to lift into the air, they require the least amount of space. However, space above the gate is required. Lift gate locations should be clear of overhead utility lines and tree branches.

Like cantilever gates, vertical lift gates hang in gate openings without the gate touching the ground. Therefore, driveway type and or snow are not factors.

Cost is the largest factor to consider. Because the operator is included, vertical lift driveway gates are substantially more costly than the other gate designs.